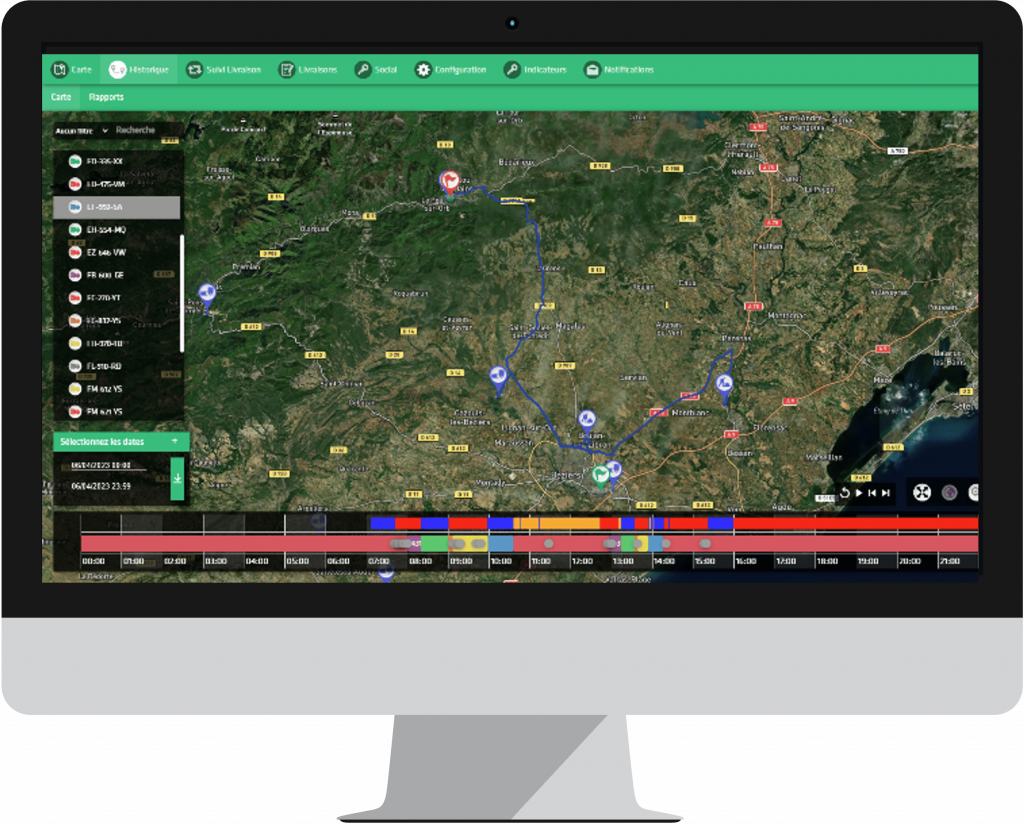

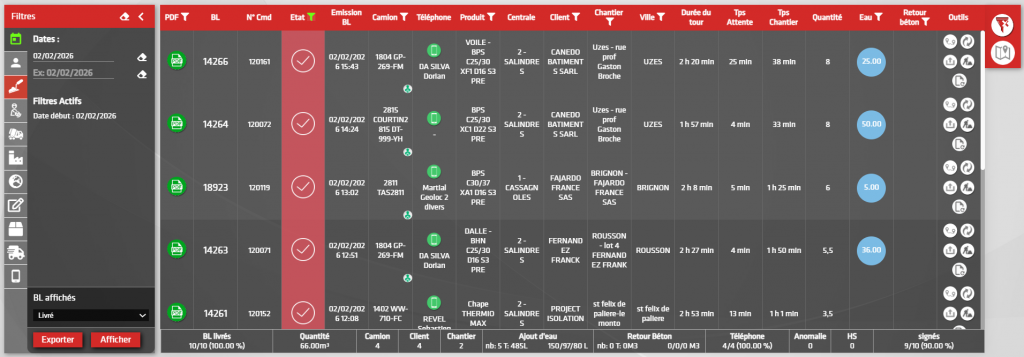

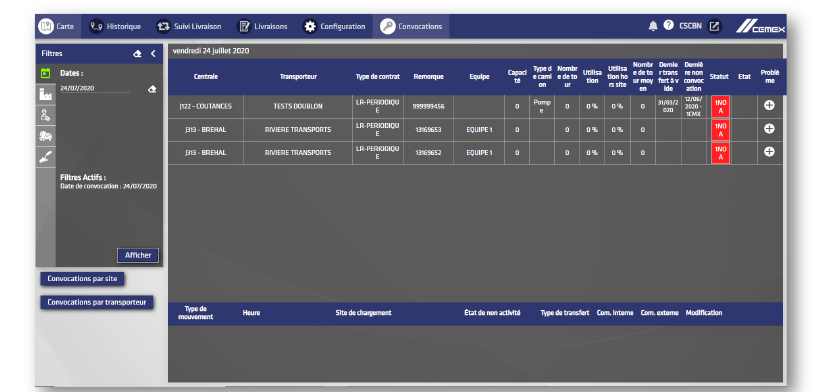

Visualize your data in real time and make informed decisions thanks to our interactive dashboards.

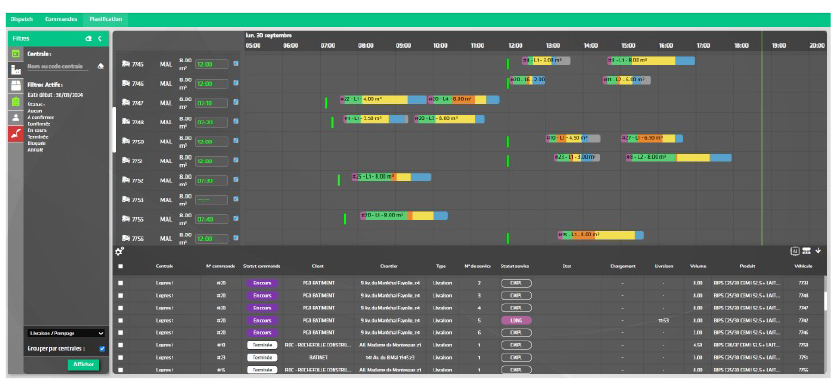

Nothing is more frustrating than a mixer truck immobilized on site or driving empty due to poor coordination.

The key to efficient concrete logistics lies in accurate anticipation and real-time visibility of your operations.

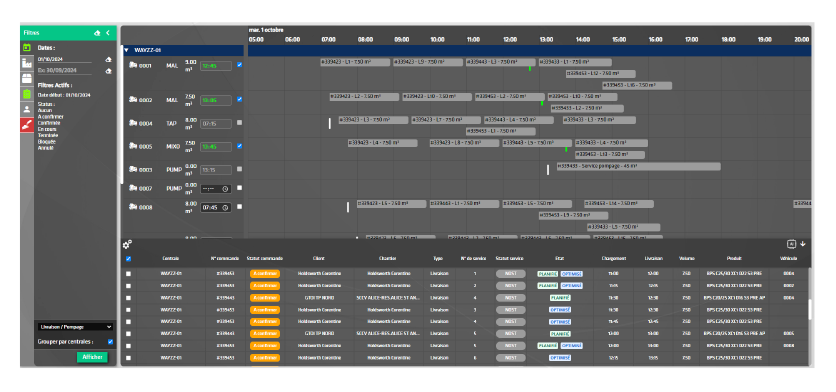

With Béton Sync’™, you manage your fleet with precision: every vehicle, every route, and every pour is tracked instantly from a single interface.

You optimize mixer truck rotation, improve team responsiveness, and significantly reduce waiting times and returned concrete.

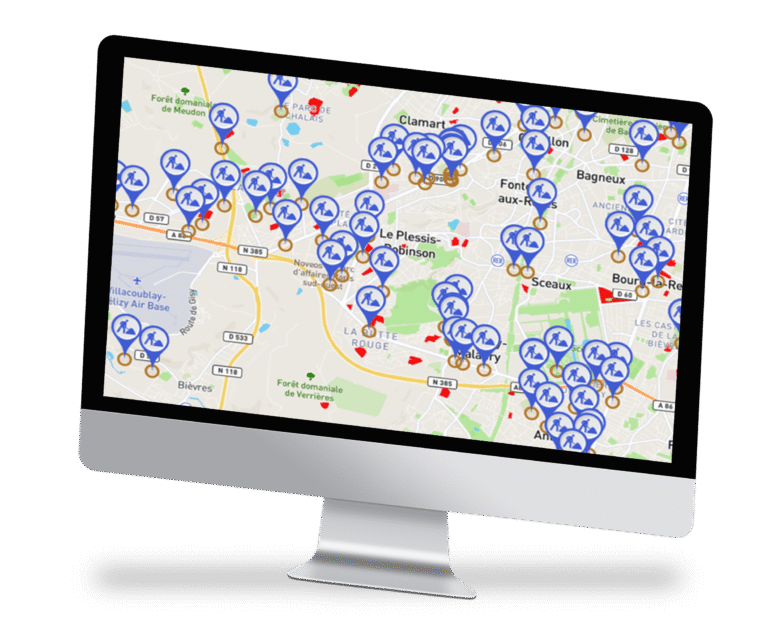

Thanks to the Béton Sync’™ visual dashboard, delivery supervision becomes clear, visual, and immediate.

Each truck is displayed according to its status: at the plant, en route, on site, unloading, or returning.

The integrated color-coding system allows plant operators and dispatch teams to instantly identify delays, blockages, or anomalies at a glance.

You gain a real-time overview of all your operations and can act immediately to adjust priorities.

Instant visibility, immediate action: the dashboard turns supervision into a true operational control tool.

Thanks to our onboard sensors and the Béton Sync’™ industry-specific algorithm, each new jobsite is automatically geolocated from the very first delivery.

The detection of the first hopper opening accurately identifies the pouring location and records the jobsite on the map.

Subsequent deliveries are then automatically linked to this jobsite, ensuring full traceability and effortless logistics monitoring.

The result: less manual input, fewer errors, and a real-time, up-to-date map of all your jobsites.

Nothing is more frustrating than a concrete mixer truck stuck on site or running empty due to poor coordination.

The key to efficient concrete logistics lies in accurate forecasting and real-time visibility of your operations.

With Béton Sync™, you can manage your fleet with precision: every vehicle, every route and every pour is tracked instantly from a single interface.

You optimise the number of trips your vehicles make each day, improve your teams’ responsiveness and significantly reduce waiting times and time spent on site.

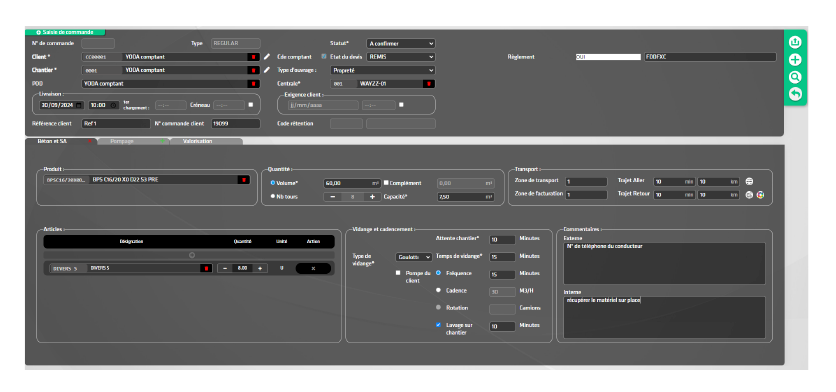

Dispatch is the operational heart of the concrete plant. It ensures coordination between customer orders, resource planning, and smooth production execution in real time.

End-to-End Support, from Installation to Deployment

To ensure a smooth and efficient onboarding of Béton Sync’, our teams support you at every stage.

Hardware installation (rotation sensors, connected flow meters, geolocation systems, etc.) is carried out by our certified installers, directly on your plants and vehicles.

You also benefit from personalized support for solution configuration, team training, and change management.

Our goal: help you fully leverage digitalization, without complexity or loss of time.

Contact us for a free audit and discover the improvement potential of your business.

Béton Sync The Modular Software Suite

With Béton Sync, activate only the solutions you need. Nothing more.

Everything is designed to scale and evolve with your business.

Production Solution

No more approximate batching: every mix is compliant, every deviation is detected.

Digitalization Solution

No more lost or unreadable delivery notes: everything is signed, archived, and accessible in one click.

Laboratory Solution

No more undetected deviations: your formulas and weighings are fully controlled.

ERP Solution

Receive delivery notes, create price offers, manage customer invoicing and supplier pre-invoicing.

Customer Solution

No more repetitive calls: your customers track deliveries and download delivery notes independently.

Hauliers Solution

Share delivery-related information directly with your transport partners.

Pumping Solution

Combine a mobile application with a real-time monitoring interface to manage pumping operations.